We transform reactive compliance into proactive risk mastery through our proven, multidisciplinary approach, which traditional single-expertise audits cannot deliver.

Your complete safety transformation includes:

✓ Independent cross-disciplinary assessment

Electrical, Mechanical, and Chemical Engineers mapping every hazard integration point

✓ Rapid deployment capability

Team mobilisation within one week – no lengthy procurement delays

✓ OEM-agnostic verification

Vendor-neutral verification eliminates costly manufacturer lock-in

✓ Digital integration platform

Seamlessly integrates with your existing asset management systems

✓ Prioritised action plans

Based on AS4024 hierarchy of controls, focus your budget where it matters most

Proven results: FMCG multinational client success story

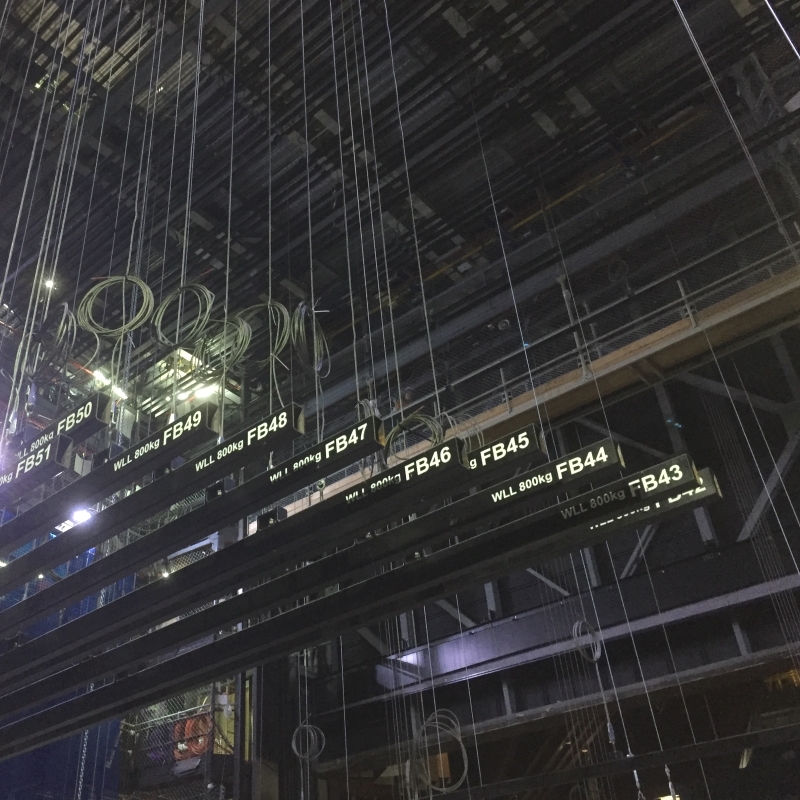

The challenge: Following a serious safety incident, a leading multinational FMCG (Fast Moving Consumer Goods) retailer needed urgent visibility of machinery hazards across their vast Australia and New Zealand warehouse network.

Our solution: Advitech’s cross-disciplinary team conducted comprehensive audits across multiple sites, recording findings against existing asset registers and delivering prioritised recommendations by machine type.

The results:

- Complete risk visibility across the entire warehouse network

- Targeted hazard elimination with clear implementation priorities

- Regulatory compliance confidence aligned with WHS obligations

- Systematic approach enabling consistent safety improvements at scale

- Empowered decision-making with data-driven insights for senior leadership

Our assessments delivered more than just a list of issues — they provided the client with a clear, prioritised roadmap for action. The client particularly valued our ability to cut through complexity and focus on the most pressing safety issues.