Advitech helped a large retailer to assess its machine safety to protect its people, meet its legal obligations, and foster a culture of safety that extends across every site.

Services

Machinery Risk Assessments

Protect your people. Ensure compliance. Improve safety.

Real-world safety. No guesswork.

When it comes to machinery risk assessments and machine safety compliance, uncertainty is not an option. Whether you’re managing a manufacturing plant, industrial site, or agricultural equipment, our machine safety engineers in NSW help you achieve AS/NZS 4024 compliance, reduce risk, and protect your team.

At Advitech, our TÜV-certified machine safety consultants, deliver tailored machinery safety audits, plant risk assessments, and machine safety system design aligned with AS 4024.1201, AS 4024.1503, and other international standards.

Read our free white paper - Machinery Safety Obligations

Looking to better understand your legal obligations around machinery safety? Download our free white paper for practical guidance on WHS compliance in NSW, including risk assessment strategies and role-specific checklists

Common challenges we solve

Not sure if your machinery meets AS 4024? We’ll assess and guide you through compliance.

Hidden hazards putting your team at risk? We uncover and address them before they escalate.

Downtime from safety system failures? We design systems that work—reliably and compliantly.

Complex safety standards? We simplify functional specs and ensure accurate system requirements.

Standards We Work To

We help you meet the latest Type C standards, including:

- AS 4024.3301 / ISO 10218-1 (Industrial robots)

- AS 4024.3101 (Milling machines)

- AS/NZS 2153.1 / ISO 4254-1 (Agricultural machinery)

- AS 1473 (Woodworking machines)

Why choose Advitech for machinery risk assessments

- TÜV-certified machinery safety engineers NSW

- Deep knowledge of AS 4024 compliance

- Decades of real-world industry experience in machine safety

- Trusted by leading industrial, mining and agricultural clients

Talk to us about:

Get in touch >

Our Services

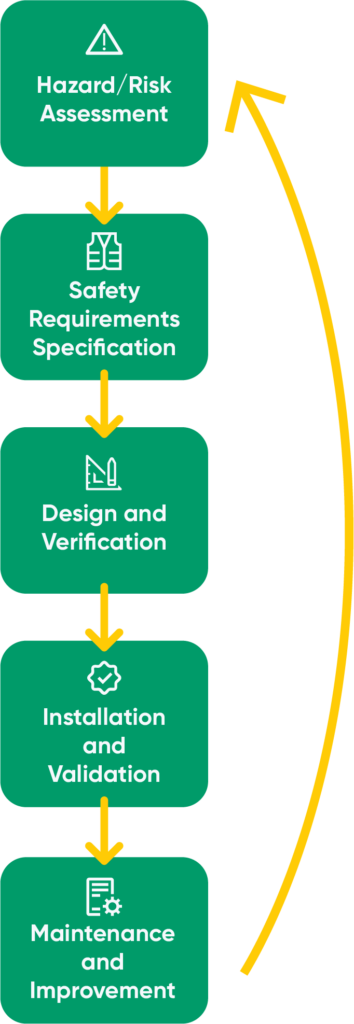

We follow a Safety Lifecycle Approach to deliver complete, compliant machine safety solutions.

Hazard/Risk Assessment

Identify hazards. Prioritise risks. Build a safer foundation.

- Machinery risk assessments

- Plant and equipment risk assessments

- Industrial equipment risk assessment

- WHS machinery risk assessment

- Machine guarding assessment

Determine Safety System Requirements

We assess safeguarding options and apply mitigation techniques to ensure your machinery meets safety standards.

- Define safety functional requirements

- Determine safety system requirements

Design and Verification

Design safety systems that work and prove they do.

- Safety circuit design

- SISTEMA verification

- Performance Level (PL) compliance (AS 4024.1503)

- Machine safety system verification

Validation

Make sure your systems perform when it matters.

- Safety System Validation

- Normative conformance audits

Ongoing Compliance & Maintenance

Stay compliant with regular audits, upgrades and preventative maintenance.

- Machinery compliance audits

- Equipment compliance audit

- Machine maintenance safety

Operational Technology (OT) Security

Stay compliant with regular audits, upgrades and preventative maintenance.

- Risk-based OT cybersecurity services

- Secure your industrial plant risk assessment and control systems

Case studies:

Verifying Emergency Stop Systems – Compliance and Worker Safety

A regional water facility partnered with Advitech to verify its emergency stop system before a major pump upgrade. The system was assessed against AS4024.1503 and NSW WHS regulations, with expert recommendations delivered in just three weeks. The result: verified compliance, improved reliability, and safer outcomes for frontline workers. Read the full article to learn more.